WATER TREATMENT SOLUTIONS

As a multi-national organization, ZI-CHEM Water Treatment provides specialist solutions for all industrial water treatment applications directly to our customers within Southeast Asia.

This includes R&D, optimized product sourcing, field evaluation and performance verification.

We work through our own local organizations, in addition to a network of accredited distributors throughout South Asia and Southeast Asia.

As an expert in water treatment formulations and application technologies, including our own regional chemical manufacturing facilities, experienced technical specialists and field service teams, we deliver solutions to our business partners which help them to fulfill their requirements for plant protection, optimal operational performance and environmental sustainability.

Providing those integrated solutions through the following primary channels:

Field consultancy provided by qualified, trained and experienced personnel

Chemical treatments from comprehensive ZI-CHEM® specialty product range

An extensive range of plant equipment of many designs

Global resources but with a regional focus

WATER TREATMENT CAPABILITIES

Sectors of

Specialization

ZI-CHEM Water Treatment comprises specialized water treatment solutions to all applications to be found in the following sectors:

Industrial manufacturing

Power utilities

Mining and minerals processing

Refrigeration and commercial air conditioning

Our trained and experienced personnel offer broad experience in applied technical program development in all water related applications and within the broad sectors outlined above. Service and solutions that are already active in many countries and many markets.

Our products also have a proven track record of performance in all the industries that we serve.

Approach to

Water Treatment

Our water management program is based on the following key approaches:

Water treatment is not just the supply of chemicals and equipment. The most effective water management programs are based on the comprehensive knowledge and utilization of consulting technology along with appropriately selected equipment, plant and chemicals. The value we bring to our clients is in the skill we apply to utilize all of these components.

Before we offer a water management program, we diligently and expertly gather and understand detailed plant technical and operational data, including past operating experiences. This enables us to develop a comprehensive program that is relevant to our client’s specific application.

The most effective results are achieved by the careful development of a water management program, followed by the effective implementation and maintenance of that program.

Our ongoing program must be adjusted, say, if site operational conditions should change and the requirement for the combination of optimum technical design and practical economics is necessary for a well-designed water management program.

The true test of the viability of our water treatment program is that the cost should be significantly less than the savings it achieves on a client’s plant.

Advanced Computer

Modelling

To correctly manage all the factors that can influence the outcome of the operation of cooling tower or steam boiler operation requires considerable technical knowledge, the right tools, and the skills to use them. A complexity that requires ability, experience and aptitude.

The computerised predictive water modelling software package from ZI-CHEM is arguably the most advanced practical application software for industrial evaporative cooling towers and boilers available in the market today in this region.

When operated by trained technicians, these computer model design programs allow accurate prediction of all critical parameters that can influence the outcome of a water management program, and allow for the selection of the most effective program at the most efficient cost.

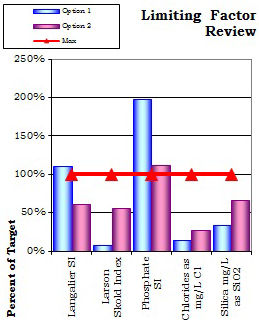

One of the most important components of the ZI-CHEM water design model for open cooling tower systems is the “Limiting Factor Review”. This is the first primary step in determining which several critical competing objectives will “Limit” the efforts to minimise cost.

Data from plant operating conditions is entered into the model, including makeup water analyses, makeup water flow, recirculation rates, volume, maximum skin temperature and supply/return temperatures. Targets for critical performance criteria are also entered for various types of scale deposition and corrosion are also added. The levels of these are often determined by the performance capabilities of the chemical treatment program that is selected.

The model then shows which factor will be reached and/or exceeded first. The user can then adjust various variables to ensure that all variables are controlled within target range and the most efficient program is selected.

This computerized model can also be used for troubleshooting existing systems, and has frequently been used to accurately identify the cause of major plant failures and the successful design of alternative programs to prevent a re-occurrence in the future.

Summary of

Benefits

Up to date technology: We can provide the very latest in research and development technology available on water treatment; quite often to a level beyond that which many locally based companies can offer.

Applied technology: More importantly, this technology is applied to the specific situation by experienced, well trained water treatment engineers on an on-going basis. This is most important. All too often, sophisticated technology can be introduced without proper consideration for the details of where it is going to be used. On the other hand, someone with a ‘little knowledge’ and back up provides inadequate technology. The consequence of both is that at best the customer receives limited benefit, or at worst they may be severely disadvantaged.

Flexible Programs: We tailor our water treatment programmed to be flexible to ensure that the individual requirements of each situation are adequately catered for in the most effective way possible. This involves the selection of treatment products and, where necessary, related equipment. We are constantly evaluating and, if necessary, modifying, our programmed to cope with any on-going changes to the plant operating conditions.

Importance of backup recognized: ZI-CHEM has, for some time, recognized the benefits of effective backup and aimed to achieve a balanced thrust of well researched technology coupled with a high level of backup. The prime goal is to ensure that our individual customers, receive maximum benefit. Our regular service visits are frequent; in addition, we aim to be readily available outside of these regular visits if required.

Final objective: In the long run, the water using plant efficiency is increased while operating costs and plant maintenance are reduced (e.g. plant maintenance, discharge costs, and fuel savings) and we thereby help to increase the profitably of the company.

There are already over 500 companies and plants taking advantage of this package in Southeast Asia

INDUSTRIES

Petrochemical

Petrochemical plants are dependent on water for many areas of the plant operation. From steam used for the process, through to cooling of many process gases and hydrocarbon liquids to enable the management of critical chemical reactions, to high purity water requirements, to wastewater treatment to protect the environment and many more.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Response to process leakage from cooling tower heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Response to contamination of steam condensate

Management of boiler feed water purity

Separation of waste oil from wastewater

Removal of COD and BOD from wastewater before discharge

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered with dedicated and experienced field service teams that are based close to or on the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Oil Refining

Oil refineries are dependent on water for many areas of the plant operation. From steam used for the process, to cooling of many process gases and hydrocarbon liquids to precisely manage critical chemical reactions, to high purity water requirements, to wastewater treatment to protect the environment.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Response to process leakage from cooling tower heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Response to contamination of steam condensate

Management of boiler feed water purity

Separation of waste oil from wastewater

Removal of COD and BOD from wastewater before discharge

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered with dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Fertilizer

Fertilizer manufacturing plants are dependent on water for many areas of the plant operation. From steam used for the process, to cooling of many process gases, acid streams, nitrogen and phosphate rich liquids, powders and granules, to precisely manage critical chemical reactions, to high purity water requirements, to wastewater treatment to protect the environment.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Response to process leakage to cooling tower heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Scale deposit control to maximize capacity and efficiency of critical cooling heat exchangers

Programs to address slime growth that results from contamination of such products as ammonia, nitrogen and phosphates

Response to contamination of steam condensate

Management of boiler feed water purity

Separation of waste oil from wastewater

Removal of COD and BOD from wastewater before discharge

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered with dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Power Utility

The operation of power utilities is critically dependent on water for maximizing efficiency and power generation rates and protection of the power generating asset from premature corrosion. Maximizing performance in these areas have a very high return on investment, given that the majority of the cost of power utilities are fixed capital for assets.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Scale deposit control to maximize capacity and efficiency of critical cooling heat exchangers

Control steam purity from boilers to protect steam turbines

Management of boiler feed water purity

Minimizing deposit weight density by reducing iron levels in return condensate

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered with dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Geothermal

Power Utility

Geothermal power utility applications are unique in that the contaminants present in geothermal steam often produce condensed water with chemistry very different to other commonly available water sources.

However, while the specific contaminants are different, the primary critical issues remain the same as other power utilities. As such these plants are also critically dependent on water for maximizing efficiency and power generation rates. Maximizing performance in these areas offers a very high return on investment, given that the majority of the costs of power utilities are fixed capital for the power generating asset.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Slime control on direct contact and surface condensers and cooling tower fill

Suspended solids control in low velocity heat exchangers

Control corrosion of steel components to maximize plant life span & plant performance

Control corrosion of concrete/cement components of cooling tower and system piping

Control corrosion of steel condensate reinjection lines

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Food & Beverage

Water is used in many areas of the food and beverage manufacturing process. Generally incoming water must be treated before use, so the water quality meets regulatory and operational requirements.

Water can be used at various stages of the process directly in contact with food, from pre-washing of product, as a transfer medium such as flume water, makeup and dilution of product batches, washing down and transport of waste from the process.

In the utilities section, water is used for the cooling of processes and machinery and for heat removal from the refrigeration process. Steam is generated to facilitate numerous processes including direct and indirect contact for sterilizing, blanching, pasteurizing, washing and other temperature process managements.

Some of the critical areas relating to water quality that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Production of water quality that is fit for purpose, either process or utilities

Managing process water disinfection to comply with regulatory requirements

Slime control in heat exchangers and cooling towers of cooling systems

Corrosion protection of cooling systems to maximize plant life & performance

Suspended solids control in low velocity heat exchangers

Scale deposit control to maximize capacity and efficiency of critical cooling heat exchangers

Management of boiler and steam to comply with regulatory requirements

Monitoring steam condensate quality and responding to process contamination

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Edible Oils

Edible oil processing plants can include palm oil, coconut oil and various other oil from crushed fruit or grain. The continuous operation of these mills is dependent on good water quality. Primarily steam is injected under pressure into autoclaves to facilitate extraction of the oil from the palm or other oil-bearing fruit. Steam is also used in steam turbines to generate electricity for the mills, many of which are in remote locations away from the main power grid.

CPO processing plants also use steam turbines to generate power in addition to heat exchangers for heating at various stages of the process. Cooling water must also be applied to various pieces of equipment along the process.

In all cases, oil contamination in the steam condensate and return cooling water is one of the primary issues that must be addressed if the plant is to be managed effectively.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Response to oil contamination in steam condensate to avoid upset to the boiler operation

Program to manage oil contamination in return cooling water

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Control steam purity from boilers to protect steam turbines

Management of boiler and steam to comply with regulatory requirements

Management of boiler feed water purity

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Tobacco

The tobacco industry also uses direct application of steam onto tobacco leaf and for temperature and humidity management inside the factory. Cooling is used extensively for utilities applications including cooling of air compressors, for utilities air, and refrigeration for temperature control.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Response to volatile organic acid contamination in steam condensate to prevent steam condensate corrosion and control dissolved and suspended iron

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Scale deposit control to maximize capacity and efficiency of critical cooling heat exchangers

Management of boiler and steam to comply with regulatory requirements

Control steam purity from boilers to protect steam turbines

Management of boiler feed water purity

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Industrial Gases

The primary water application in the manufacture of industrial gases is cooling water. This is used extensively for utilities applications, primarily cooling of air compressors for compression of product gases, gas liquification and air separation units and for utilities air and refrigeration cooling.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Scale deposit control in high temperature heat exchangers and intercoolers to maximize plant capacity and efficiency and avoid the need for frequent offline cleaning

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Steel Mills

Steel mills are dependent on water for many areas of the plant operation. Water is used to quench and cool surfaces of steel throughout many stages of the steel fabrication process, through to rolling and forming. Steam is also used for heat treatment and power utility applications.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Corrosion and fouling caused by suspended iron oxide particles

Rapid corrosion caused by oil and grease from steel handling equipment

Scale deposition on very high temperature surfaces (over 1,000°C)

Scale and suspended solids blocking cooling water spray nozzles

Suspended solids control in low velocity heat exchangers

Response to contamination of steam condensate

Management of boiler feed water purity

Separation of waste oil from wastewater

Removal of COD and BOD from wastewater before discharge

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Cement

While cement manufacturing is largely a dry process, the cement industry is still dependent on water for maximizing the performance of utilities systems such as oil cooling, compressor intercooler cooling and steam generation.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Control of scale deposits in high temperature intercoolers and other heat exchangers that is exacerbated by contamination of cement dust in the system

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Control steam purity from boilers to protect steam turbines

Management of boiler feed water purity

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Metals Smelting

Metals smelting plants and mills are dependent on water for many areas of the plant operation. Water is used to cool external surfaces of furnaces, quench and cool surfaces of product metal throughout many stages of the refining and fabrication process, through to rolling and forming. Steam is also used for the addition of heat to various parts of the refining process and for power utility applications.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Corrosion and fouling caused by suspended metal oxide particles

Rapid corrosion caused by oil and grease from metals handling equipment

Scale deposition on very high temperature surfaces (over 1,000°C)

Scale and suspended solids blocking cooling water spray nozzles

Scale deposition in smelter flue gas quench water circuits

Suspended solids control in low velocity heat exchangers

Response to contamination of steam condensate

Management of boiler feed water purity

Separation of waste oil from wastewater

Removal of COD and BOD from wastewater before discharge

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Processed Wood

The processed wood industry includes timber mills, curing kilns, and MDF plants. These utilize steam for curing of wood and wood products and cooling for utilities systems such as oil cooling and compressor intercooler cooling.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Corrosion protection of boiler systems particularly of after boiler systems

Response to volatile organic acid contamination in steam condensate to prevent steam condensate corrosion and control dissolved and suspended iron

Control of condensate quality and monitoring for contamination

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Control of scale deposits in heat exchangers

Control steam purity from boilers to protect steam turbines

Management of boiler feed water purity

Treatment of wastewater to minimize suspended solids, COD and BOD

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Refrigeration

Many large industrial refrigeration systems are dependent on water to remove heat from refrigeration chillers, compressors and evaporative condensers.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Scale deposit control in high temperature heat exchangers, intercoolers and evaporative condensers to maximize plant capacity and efficiency and avoid the need for frequent offline cleaning

Slime control in heat exchangers and cooling towers of cooling systems to maximize heat exchange capacity and avoid under slime corrosion

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Tyre & Rubber

The Tyre & rubber manufacturing industry uses water in many areas of the process. These include direct contact cooling and curing water and steam, indirect steam and cooling via heat exchangers, heat exchangers and Moulds, and utilities cooling of air compressors, oil coolers and other machinery.

Some of the critical areas that must be focused on in order to ensure the reliable and efficient operation of the plant include:

Corrosion protection of boiler systems particularly after boiler systems

Control of condensate quality and monitoring for contamination

Slime control in heat exchangers and cooling towers of cooling systems

Suspended solids control in low velocity heat exchangers

Corrosion protection of cooling systems to maximize plant life & performance

Control of scale deposits in heat exchangers

Control steam purity from boilers to protect steam turbines

Management of boiler feed water purity

Treatment of wastewater to minimize suspended solids, COD and BOD

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results. These are delivered by dedicated and experienced field service teams that are based close to or inside the plant site to ensure attentive support and rapid responses are provided, so that the objectives of the programs are achieved.

Gold & Base

Metal Mining

The mineral processing facilities of gold and base metals mining operations make extensive use of water. Beginning at the mills, the crushed ore is transported as slurry through the processing plant. The water is eventually separated from the metal concentrate or waste tailings and returned to the mill for re-use. The recycle stages include thickener overflow, tailings return and process water feed.

The primary objective of ZI-CHEM water management programs in these systems is to reduce the scale deposition in the mill water circuit water lines, pumps, pressure regulating valves, sprinklers and laterals by the most effective means available. This will achieve the following benefits for the mill operations:

Eliminate manual cleaning of pipes, pumps & valves

Avoidance of unscheduled plant downtime and offline cleaning with associated cost

Reduced electricity usage by reducing elevated head loss in pumps and pipes

Perform these improvements at less than the costs of the problems it resolves

The water management programs developed by ZI-CHEM are based on global technologies that have been applied in the field for many years and refined to optimize and enhance results.

The key components of the scale control management program include:

An advanced program designed to analyze data and predict the potential for scaling

Customized action plan that is the most practical response to minimize plant disruption & inefficiencies caused by scale deposition

A comprehensive scale control program consisting of an integrated package of service, chemicals, feed & monitoring equipment and technical support

Provision of advanced application technologies for reducing scale deposition in critical heat exchangers

Managed product supply systems to ensure the reliable and efficient supply of products required and management of associated inventory

PRODUCTS & SERVICES

CUSTOMISED SOLUTIONS FOR REACH APPLICATION

International Techology

with regional focus

Field Support services

Equipment

Technologies

Quality Specialty

Chemical Products

Advanced Field

Consulting Services

ZI-CHEM® Specialty Water Treatment provides a complete source for the provision of a broad range of advanced industrial water management solutions through the following primary channels:

Field consultancy provided by qualified, trained and experienced engineering personnel

Chemical treatments from comprehensive ZI-CHEM® specialty product range

An extensive range of plant equipment

Site services by trained & experienced service team

Global resources but with a regional focus

WATER TREATMENT CHEMICALS

ZI-CHEM®

Chemical Range

ZI-CHEM® specialty chemical treatment range comprises over 250 specialty chemical products and is designed to allow our specialist field technicians and engineers to customize treatment programs for your specific plant and prevailing operating conditions – planning and working within your budget.

Some of the primary product groups in ZI-CHEM® specialty water treatment range include the following:

ZI-CHEM 1100 series boiler water scale deposit control systems

ZI-CHEM 1200 series boiler corrosion inhibitor oxygen scavengers and metal passivators

ZI-CHEM 1300 series boiler pH adjustment products

ZI-CHEM 1400 series steam & condensate volatile corrosion inhibitors

ZI-CHEM 1500 series steam boiler foam control products

ZI-CHEM 2100 series cooling tower scale deposit control programs

ZI-CHEM 2200 series specialist cooling water corrosion control programs

ZI-CHEM 2300 series cooling tower pH adjustment products

ZI-CHEM 2400 and 2500 series microbiological and slime control programs

ZI-CHEM 2600 series specialist cooling tower suspended solids and biofilm dispersants

ZI-CHEM 3000 series closed circuit cooling and heating treatments

ZI-CHEM 4000 series saltwater desalination and brine concentrator treatment products

ZI-CHEM 5000 series specialist mining scale control treatments

ZI-CHEM 6000 series Reverse Osmosis membrane treatment range

ZI-CHEM 7000 series clarification and liquid solids separation technologies

ZI-CHEM 8000 series offline cleaning and corrosion protection systems

ZI-CHEM 9000 series specialist industrial process water products

These products are rigorously tested and evaluated under actual operational conditions before use in the market. Once quality targets have been met, we select our raw materials from local sources in order to facilitate our optimized supply chain management program, enabling us to pass these savings onto our customers.

Chemical Treatment

Programs

Some of the primary water using applications ZI-CHEM operates in include:

Raw water treatment from deep wells, rivers and surface reservoirs including removal of suspended solids, dissolved solids, dissolved gasses and micro-organisms

Desalination evaporators or seawater RO

Open evaporative cooling water treatment including cooling towers, evaporative condensers, and air washers

Closed loop cooling water treatment

Water treatment of entire steam generating systems including feedwater, boiler steam & condensate systems

Pre-commission cleaning of water using systems

Off-line cleaning of heat exchangers including boilers, shell & tube heat exchangers, evaporators

Scale deposit control in process water applications including food industry

Waste water treatment before disposal or reuse

Sludge de-watering specialist mining process water applications

Reclamation of plant water for specific re-use applications

Product Supply

& Distribution

Our regional manufacturing base, located in Singapore, has both ISO 9002 Quality Control and ISO 14001 Environmental Accreditation.

Our operations include offices and managed warehousing based in every capital city of the countries in which we operate. In addition, these are supported by numerous branch offices and laboratories in the regions where we provide field services.

This distribution network ensures that deliveries to our customers are guaranteed on time, every time, in addition to providing a ‘buffer’ to cover for unforeseen circumstances.

WATER TREATMENT SERVICES

Advanced Field

Consulting

Technology is of no benefit without correct application. For water treatment, this is a defined process, comprising of several primary components.

Personnel Resources

ZI-CHEM technologies recognize that our people are one of our most important resources, and the most crucial factor in ensuring the package we provide is world class. To achieve this, we focus our efforts on selecting people with goals and an outlook aligned with that of our business. Then the skills of every employee are developed on an on-going basis by the ZI-CHEM skills enhancement program. This program continues for the entire period that our personnel remain part of the ZI-CHEM team.

It follows the following primary steps:

Starting with intensive introductory orientation

Progressing to advanced technologies

Continuing with technology updates, specialist focus topics and refresher courses

Experience is also essential to the comprehensive development of the skills of our customer service and technical support personnel. As a team, we maintain a primary core of industry experienced support personnel, each with an average experience of 10 – 20 years.

Plant Survey

Before making any meaningful recommendations or implementing any program, a comprehensive understanding of the specific application is required. The plant survey will include many of the following components:

Review of system design and operational data

Physical inspection of the plant during operation and/or out of operation

Analysis of water chemistry, micro biology and review of historical data

Discussion of relevant operational experience with plant operations personnel

Discussion of relevant maintenance results with plant maintenance personnel

Comprehensive survey report with assessment of the data collected

Determination of Objectives

Identifying the key objectives of the plant stakeholders including:

Operational (e.g. plant capacity, reliability and quality)

Maintenance (e.g. equipment life, repairs and replacement)

Economic (e.g. operational costs affected by water including fuel, water and labor)

Development of Program Design

After the survey and determination of objectives, both are reviewed and matched with the most appropriate technologies currently available. It is not uncommon that more than one option is also offered. This allows for an informed decision to be made relative to what is available in the market. Options are normally a comparison of different capital costs vs operating costs, or the performance level of the chemical program. This can include various levels of automation & control, pre-treatment equipment.

Design Report

A comprehensive report of the survey data and recommended program design options is prepared by ZI-CHEM personnel and presented to the relevant stakeholders and interested parties.

Implementation

After the program design is agreed upon, a detailed implementation plan is prepared and implemented. This can include any or all of the following components:

Design, build install and commission selected plant and/or equipment

Establish operational KPI’s & KCP’s for ongoing operation of plant and treatment program

Training of site personnel

Introduce selected chemical treatments

Set up and maintain detailed monitoring program including field analyses, laboratory analyses, use of various portable or permanent field diagnostic equipment

Regular inspection of critical plant when available

Conduct regular review of actual operating results against KPI targets

Site Assessment

Surveys

Purpose

A successful water treatment management program is contingent on a high level of technical support. The quality of this support is proportional to the depth of knowledge we have of the specific plant being managed.

ZI-CHEM Approach

ZI-CHEM takes the local consulting component of their water treatment responsibilities very seriously. In situations where ZI-CHEM is being considered as a potential new provider of water treatment management services, it is our policy to ensure we have an in-depth knowledge of the plant first.

Survey Summary:

Duration: This will depend on the scope and complexity of the situation. Survey periods range from 1 week to 3 years; and average 6 months.

Time input: This is also dependent on the situation. Survey and monitoring visits can be conducted from 1 – 10 times per month, and even full time daily. Hours on site per visit can range from 1 – 4 hours per visit.

Equipment: Monitoring equipment may be required. This can include portable equipment, temporary on-line monitoring/data logging equipment, scale probes, corrator probes, corrosion coupons and the like.

Reporting: It is our normal procedure to provide progress reports to plant personnel on a regular basis.

Cost: Since it is us who are gaining this knowledge, we consider it reasonable that we do not always make charges for these activities.

Engineering Services

The ZI-CHEM engineering services program is a structure designed to manage the full-service program, provide technical advancements and take responsibility for achieving targeted results.

Site Engineering Service

Site based service engineers’ who perform tasks including:

Inventory management

Chemical tank filling

Chemical dosing, adjustment & control

Water analysis in field and laboratory

Microbiological analysis diagnosis

Corrosion rate monitoring

Heat exchanger performance monitoring

Heat exchanger performance monitoring

Provision of equipment

Supply, install, commission, maintain, and operate:

Chemical storage

Chemical feed pumps

Injection lines

Specialist chemical feeders and generators (e.g. chlorine dioxide)

Online monitoring, datalogging, auto control

Management

Site based engineers:

Local regional based account manager

Corporate based senior specialist engineers

Corporate based expatriate regional technical support

Regional support in Singapore, Thailand, Australia, USA

Schedule of review meetings, process improvement projects

On-site Analytical

Services

ZI-CHEM capabilities include the provision of a wide range of on-site analytical services for water-using systems. This data is provided to customers by frequent and regular reporting methods including trending with commentary. It is also used to make critical adjustments, in order to manage water chemistry within prescribed operating ranges that are acceptable for the effective management of water treatment objectives.

Range of sample collection and analyses:

Surface water

Deep well waters

Clarifier overflow and underflow

Softened water

Demineralizer product water

Reverse Osmosis feed, permeate, recycle, brine

Boiler feedwater

Boiler water

Saturated steam

Condensate return

Cooling tower makeup

Cooling water supply and return waters

Closed cooling water circuits

Analytical methods employed:

Electronic meter including pH, conductivity, ORP, linear polarization

Wet analysis titration for anionic compounds including hardness (total, calcium, magnesium), alkalinity (total, OH), sulfite, chloride

Spectrophotometric analyses for iron, silica, phosphate, phosphorus, zinc, molybdate, sulfate, DEHA, hydroquinone, hydrazine, amine

Microbiological including plate count, displide, ATP, slime adhesion, SRB

Clarification including suspended solids, turbidity, color

WATER TREATMENT EQUIPMENT

Water Treatment Equipment

ZI-CHEM has recently expanded its water treatment products and services – strengthening water treatment capabilities in the equipment design and engineering arena. This in addition to our already strong competencies in the water treatment chemicals products division will allow ZI-CHEM to offer an even greater degree of complete bespoke water treatment solutions to all existing and future customers.

From incoming raw water to wastewater treatment and recycling for industrial applications; our ZI-CHEM technical and engineering specialists can design, supply, install and commission the right package water treatment plant to implement the best solution for your requirements.

Package plants, also known as modular systems, take up less space and contain few moving parts. The result is an efficient, highly reliable and affordable potable water treatment plant or wastewater treatment plant with low maintenance and operating costs.

Some of the primary packages we can offer include:

High rate or conventional clarification plants

Media and mixed media filters

Ion exchange softeners

Ion exchange Demin, polishers

Membrane filtration including MF, UF

Reverse osmosis (raw water, sea water, brackish water, recycling)

Containerised WTP

Biological treatment including aerobic, anaerobic, MBR

Sludge dewatering filter presses

Chemical storage, mixing and feed systems

KEY SOLUTIONS FOR INDUSTRY

Corrosion Protection

Programs

Effective corrosion protection programs can save significant costs to repair or replace equipment that is affected by corrosion.

Following is an overview of the steps taken to design and implement a comprehensive and effective corrosion protection program for water using systems including steam boiler systems, and cooling tower systems:

1- Plant Assessment

Study plant design, operation, and water chemistry.

Review historical results, including plant inspections.

Modelling to predict the potential for corrosion.

2- Program Design

Pre-treatment equipment: de-aerator, de-alkalization, RO, other.

Chemical type: Oxygen scavenger, metal passivator, filming, volatile, nonvolatile.

ROI study: Capital vs operational cost vs amount saved by reducing corrosion rate.

Program justification: Select program based on most attractive ROI.

3- Implementation

Pre-treatment equipment: Install & commission.

Chemical dosing equipment: Install & commission.

Chemical program: Initial dose and continuous dose.

KCP monitoring: Analyses of chemical residuals, water corrosion indices, dissolved oxygen

KPI monitoring: Corrosion rates by coupon, LP corrator.

Review: Actual vs target and make adjustment to chemical program if needed.

Increased Steam

Capacity

The capacity of a given steam boiler system to generate steam is influenced by many factors.

One of the primary factors is the rate of heat transfer from the combustion side of the boiler tube into the water on the other side of the tube wall. If this rate is reduced, then the heat will pass through the tubes before it can be transferred to the water to generate steam. The energy is then lost as hotter flue gasses to the atmosphere.

If scale deposits are present on the tube, these can greatly reduce rate of heat transfer. This is depicted in Figure 1 below. In addition, table 1 below shows the rate of heat transfer of boiler steel compared to common scale deposits.

Figure 1 – Heat Transfer Path

Table 1 Thermal Conductivities

| Heat Exchanger Materials | Thermal Conductivity (K) |

|---|---|

| Tube Steel | 310 |

| Insulating Brick | 0.7 |

| Scales | |

| Calcium Carbonate | 16 |

| Calcium Silicate | 8 |

| Calcium Sulphate | 16 |

| Magnesium Phosphate | 15 |

| Silicate Scale, Porous | 0.6 |

| Sludges | |

| Calcium Hydroxyapatite | 18 |

| Serpentine | 17 |

| Iron Oxide | |

| Magnetic Iron Oxide | 20 |

ZI-CHEM® chemical program technologies offer an extensive range of advanced efficiency management systems, to ensure effective control of scale deposition is achieved to ensure heat transfer capacity is maximized.

This begins with computer modelling of actual vs design, through to extensive program design and implementation including:

Pre-treatment equipment design

Pre-treatment equipment optimization

Comprehensive computerized chemistry modelling of water quality

Advanced polymer based chemical programs

Plant performance monitoring systems

Scale Control

Programs

In today’s world, maximizing performance, productivity and efficiency are critical to the success and survival of any operation.

The primary objective of our scale deposit programs in process water applications is to reduce the scale deposition in the water lines, manifolds, pumps and valves nearest to the manifolds by the most effective means available. This will achieve the following plant improvements:

Eliminate manual cleaning of pipes, pumps & valves

Reduced plant downtime & cost associated with cleaning.

Reduced electricity usage by reducing restriction in pipes and associated head loss.

Scale control in water using systems is not just chemicals. The most effective water management programs are based on the comprehensive knowledge and utilization of consulting technology, equipment, plant and chemicals.

The key components of the ZI-CHEM scale control management program include:

Advanced program development to predict scaling potential and develop a customized response that is most practical response to minimize plant disruption & inefficiencies caused by scale deposition.

Comprehensive scale control management program consisting of an integrated package of service, anticalin chemicals, feed & monitoring equipment, and technical support.

Managed product supply systems to ensure the reliable and efficient supply of products required and management of associated inventory. Introduction of the ZI-CHEM “shared responsibility for outcomes” program management policy. Provision of additional monitoring data in regular reporting.

Provision of advanced application technologies for reducing scale deposition in critical heat exchangers.

Low Toxicity

Oxygen Scavengers

The ZI-CHEM® product range includes oxygen scavengers for a wide range of operating conditions and application requirements found in industrial steam generating applications.

Some of the key criterion that is considered when selecting the most suitable oxygen scavenger for a given application includes:

Oxygen exchange capacity

Speed of reaction with oxygen

Contribution to boiler dissolved solids and resultant blowdown or scale deposition

Degree of volatility

Metal passivation capability

Solubilization of surface iron and copper oxides

Toxicity

Degree of carcinogenic risk

Oxygen scavengers such as hydrazine have been used extensively in the past, and in some places are still in use. However, there is now increased awareness that hydrazine is highly toxic to humans and is also a suspected carcinogen.

Within the ZI-CHEM® product range there are many safer alternatives to hydrazine that exhibit equal or higher performance but have little or low toxicity and are non carcinogenic.

A summary of the features of the most common components contained in these products of these is shown below:

| Chemical | Oxygen Scavenging | Passivation | Volatility | Breakdown Pressure | Residual Testing | Safety |

|---|---|---|---|---|---|---|

| Sodium (Bi~) Sulfite (Na; SO3, NaHSO3) | Excellent | Little to None | Non-Volatile | 900-1250 psig SO2, H2S | Very Good (Boiler Water) | FDA Acceptable |

| Erythorbate (C6H7O6Na) | Very Good | Excellent | Non-Volatile | 1200-1600 psig CO2, Organic Acids | Good (Feedwater) | GRAS |

| Methyl ethyl ketoxime C4H8NOH | Good | Excellent | Excellent | 1250 psig NH3, N2O, N2, MEK | Good (Feedwater) | Moderately Toxic |

| Diethyl Hy doxylamine (C2H5)2NOH | Good | Very Good | Very Good | 300 psig NH3, NO2, NO3, Amines, Acetate | Good (Feedwater) | Moderately Toxic |

| Hydroquinone C6H6O2 | Very Good | Good | Non-Volatile (Steam Distills) | 1300 psig CO2, Organic Acids | Good (Feedwater) | Mutagenic |

| Carbohydrazide (N2H3)2CO | Good | Fair | Poor | 235 psig NH3,N1, CO2 | Poor (Feedwater) | Unstudied |

| Hydrazine N2H4 | Good | Good | Poor | 235 psig N2, NH3 | Very Good (Feedwater) | Suspect Carcinogen |

Slime Control

Programs

Microbiological slime is prevalent and can cause many problems in many industrial processes, and includes water used in food processing through to heat exchangers in water cooling systems. The successful application of these programs can greatly improve productivity, reduce energy costs and improve health and safety.

The ZI-CHEM® technology range comprises a comprehensive range of slime control programs based on both chemical and non-chemical technologies. These are selected and applied by utilization of proprietary application practices that have been developed based on many years of operational experience and program development.

Slime control programs include:

Traditional chlorine technology applied with:

Chlorine gas

Hypochlorite liquid

Calcium hypochlorite

Alternative oxidizing biocide-based programs including:

Trichloro cyanuric acid

Bromine

Chlorine dioxide

Non oxidizing biocide programs, some with approvals for food processing applications:

Isothiazoline

Gluteraldehyde

Quaternary ammonium compounds

DBNPA

TBTO

Triazine

Seawater antifouling biocides with corrosion inhibition properties:

Diamine

Quaternary ammonium compounds

Desalination Scale

Deposit Control

Seawater evaporators are designed to produce distilled water from sea water for use as boiler feed water, engine cooling water and domestic purposes.

The two basic types of evaporators, namely the flash and submerged element or coil type, both suffer from the problem of scale formation on their heat exchange surfaces. This scale impairs heat transfer, thereby reducing the efficiency of the evaporator and eventually necessitating evaporator shutdown for either chemical or mechanical cleaning. Therefore, there is a requirement for an effective method of controlling or preventing scale formation.

The two types of scale that occur in sea water evaporators are the alkaline hardness scales, and calcium sulphate scales. The former is composed of calcium carbonate, magnesium hydroxide and occasionally magnesium carbonate. Other compounds are found in scales however, resulting from absorption or co-precipitation. The nature and composition of the scale formed is dependent on the operating temperature of the evaporator and to a lesser extent on the brine concentration in the evaporator.

The ZI-CHEM® range of specialist scale deposit inhibitors are comprised of specially prepared formulation of low molecular weight synthetic polymers designed to give maximum protection against all common types of scale, throughout the entire temperature range of existing evaporators. It is equally effective for flash or submerged element types.

These products prevent scale formation by a “threshold” mechanism, i.e. a small amount of treatment when added to the seawater prevents precipitation of a large amount of hardness salts. This causes a delay in precipitation of all alkaline hardness at the time when precipitation would normally occur.

Also, the normal crystalline structure is so distorted that a fine sludge occurs, which does not compact but remains in suspension. This can be easily removed using the brine blowdown or deconcentrator.

With non-alkaline hardness such as calcium sulphate these programs give a stabilizing effect to the supersaturated solution, resulting in up to two times the normal solubility of calcium sulphate being achieved.

Increased Cooling

Capacity

A thorough understanding of the factors that affect the capacity of cooling water heat exchangers to remove heat from critical industrial process is essential if a program is to be effectively designed that can maximize the heat transfer capacity in an operating plant.

The graph below shows that scale deposits, biofilm from microbiological growth and iron oxide deposits can all reduce heat transfer capacity.

The ZI-CHEM® cooling water program includes the capabilities to predict and measure the various components of the scale deposits, and the chemical programs to minimize these, along with monitoring systems to evaluate the result, and optimize the performance on an ongoing basis.

Reverse Osmosis

Optimization

During normal operation over a period of time, RO membrane elements are subject to fouling by suspended or sparingly soluble materials that may be present in the feedwater. Foulant removal is achieved by cleaning and flushing or by changing the operating conditions.

As a general guide, foulant removal is required when any of the following conditions occur:

Permeate flow has dropped to 10-15 percent below rated flow at normal pressure

Feedwater pressure has increased 10-15 percent to maintain rated product water flow

Product water quality decreases 10-15 percent;(increased conductivity)

The differential pressure across an RO stage has increased noticeably

ZI-CHEM® Reverse Osmosis maintenance technologies include a broad range of chemistries that are supported by cleaning and monitoring procedures. These are designed to maximize the performance of ion exchange membranes and avoid costly premature replacement of spent membranes.

These programs can address foulants caused by a wide range of sources including:

Bacterial Fouling

Organic Deposits (inlet and first pass end of system)

Mixed Colloids of suspended organics, and silicates, iron at inlet and first pass

Hydrated Oxides (iron, nickel, copper, etc.)

Calcium Precipitates (carbonates and phosphates (concentrate end of the system)

Calcium Sulfate (concentrate end of the system)

Silica Based (including precipitates and aluminosilicates)

Diesel Engine Cooling

System Corrosion

Control Programs

Diesel Engine Cooling System Corrosion Control

Large static diesel engines are used extensively in small to medium sized electricity generation. These can be found in industrial, mining and utility applications.

Many of these systems utilize closed cooling circuits. These are not subject to the effects of external contamination and cycles of concentration that occur in open evaporative cooling systems. However, corrosion and microbiological growth can often occur if the system is not managed correctly. Some of the causes for this include:

Insufficient recommission cleaning and passivation at time of system commissioning

Contamination of bacteria present in makeup water

Use of nitrite-based corrosion inhibitors that can provide a food source for bacteria

Absence of microbiological monitoring and treatment program

If not managed correctly, severe failure and disruption to plant operation can occur. To avoid these, ZI-CHEM offers a comprehensive range of chemical and application technologies to manage the water quality in these water circuits. These include:

Online corrosion measuring systems

Range of multi-component corrosion and scale inhibitor programs

Non-nitrite-based corrosion inhibitor programs

Microbiological monitoring programs to diagnose and predict problems

Chemical biocide programs

Inline bypass filtration systems to remove suspended iron

Comprehensive program management and reporting by experienced personnel

Chlorine Dioxide

Disinfection

Chlorine dioxide is a specialist oxidizing biocides that offers a number of advantages for water disinfection compared with other disinfectants such as chlorine:

7 times stronger oxidant than chlorine

Selective oxidant and so does not react with many process contaminants, organics

Extremely effective biofilm dispersant

No dangerous by products e.g. THM’s

Low impact on corrosion

Wide range of applications:

Disinfection of drinking water

Disinfection of wastewater

Phenol destruction in wastewater systems

Effective control of legionella in cold and hot water systems

Water disinfection in air conditioning system cooling towers

Disinfection of product and service water

Bottle cleaning, rinse and pasteurizer

Cold sterile bottling

Disinfectant in CIP systems

Condenser water treatment (condensate) in the milk industry

Disinfection of wash water for fruit, vegetables, seafood, fish, poultry

Cooling water treatment

Seawater cooling control of mussels and planktonic organisms

Combating legionella in cooling circuits

Disinfection of process water

Removal of odorous substances in air scrubbers

Specialist Generation Techniques

Chlorine dioxide is an extremely reactive gas, which because of its instability – cannot be stored and must only be produced in the required quantities in special generators on the site where it is to be used.

The ZI-CHEM® technology is based on a new generation of chlorine dioxide generation systems that utilize both two and three chemical pre-cursor processes.

This compact unit produces clean ClO2 on demand by mixing controlled amounts of 25% sodium chlorite with either gaseous chlorine, or sodium hypochlorite and hydrochloric acid.

Chlorine dioxide is generated in the revolutionary new dual ZI-OX reaction columns. The chlorine reacts in milliseconds with the chlorite stream to produce chlorine dioxide which is immediately diluted into the motive water stream.

ZI-CHEM ZI-OX Chlorine Dioxide Generators- Key Features-

Multi-level safety features

High efficiency reaction up to 95%

Simple rapid installation

Simple to operate & maintain

Small footprint for maximum space utilization

Option for auto control of feed rate proportionate to demand using on-line instrumentation that measures residual Low cost Proven technology in many applications